What next for the supply chain?

The fashion industry has been rocked by the Covid-19 pandemic. In the next part of our series, we look at the implications for the supply chain.

Summer is cancelled

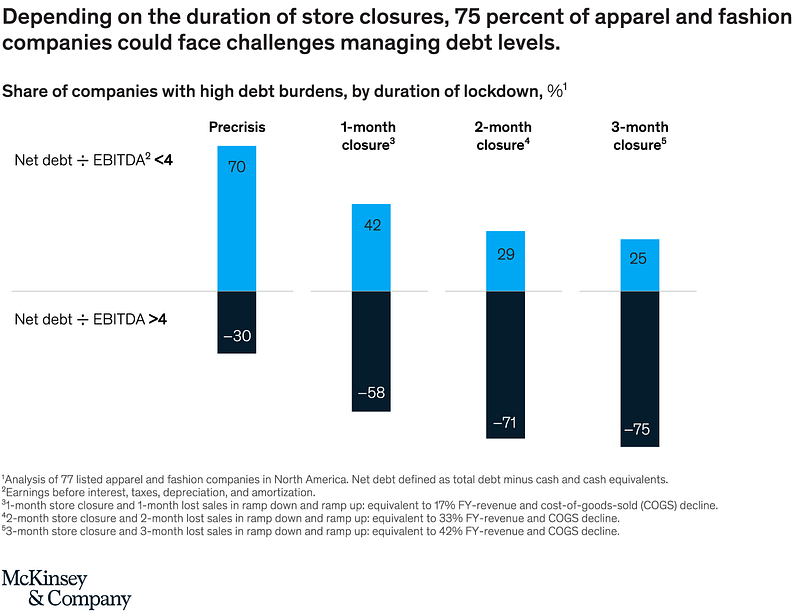

Dwindling demand, coupled with lockdown-induced store closures, had a dramatic effect, and sudden effect. In early April, Gap Inc effectively pressed pause on its summer and fall orders, asking suppliers and fabric manufacturers to stop production. It also halted the shipping of any completed orders not destined for its online stores.

Gap, of course, had already been struggling to remain relevant in a competitive fast fashion world, but it was not the only brand cancelling orders. By the beginning of June, the Business & Human Rights Resource Centre’s Covid-19 tracker reported that UK retailers had cancelled $2.5 billion of orders in Bangladesh, suspended workers in Cambodia had suffered a 67 percent wage drop, and 75,000 workers in Bangladesh had not been paid for March.

The human cost of cancelled orders

Blocking production puts fast fashion manufacturers based in South-East Asia at risk because countries like Bangladesh, Vietnam, Cambodia and Indonesia rely heavily on apparel exports. Scott Nova, executive director at the Worker Rights Consortium, told The Guardian that, “While it is understandable that companies are focusing on the needs of their local staff, clothing retailers must accept that if they choose a business model that relies on the labour of millions of garment workers overseas, then these people are their workers as well.” How will these workers support themselves without a safety net? What will their health conditions be like? When will they be able to get back to work?

Order cancellations put global fashion brands under the spotlight. While some companies, including H&M and Inditex (which owns Zara), committed to paying in full for completed orders and orders still in production, at the time of writing many others, such as Arcadia and Urban Outfitters, had not.

A way forward

So who got it right? Fashion brands who quickly pivoted to producing PPE, like Barbour in the UK and Armani in Italy, earned a positive press. In the same spirit, smaller brands like California-based Christy Dawn and Reformation, both of which have built their brands around championing sustainability, produced non-surgical face masks. In Scotland, a company called Lost Stock was set up to sell boxes of rejected or cancelled stock directly to consumers, helping to support workers and their families and saving the garments from landfill.

The pandemic has broken the vicious cycle of overproducing and overbuying, grounding customers and giving businesses an opportunity to reinvent themselves and to redefine the balance between supply and demand. Here at Maakola we’ve been championing a way forward with our made-to-order model, and it’s been cheering to find that we are part of a trend. With more and more small labels making their clothes to order, consumers are learning to replace instant gratification with slow fashion — becoming more selective about what they buy, and being prepared to wait for it.